top of page

812.414.5705

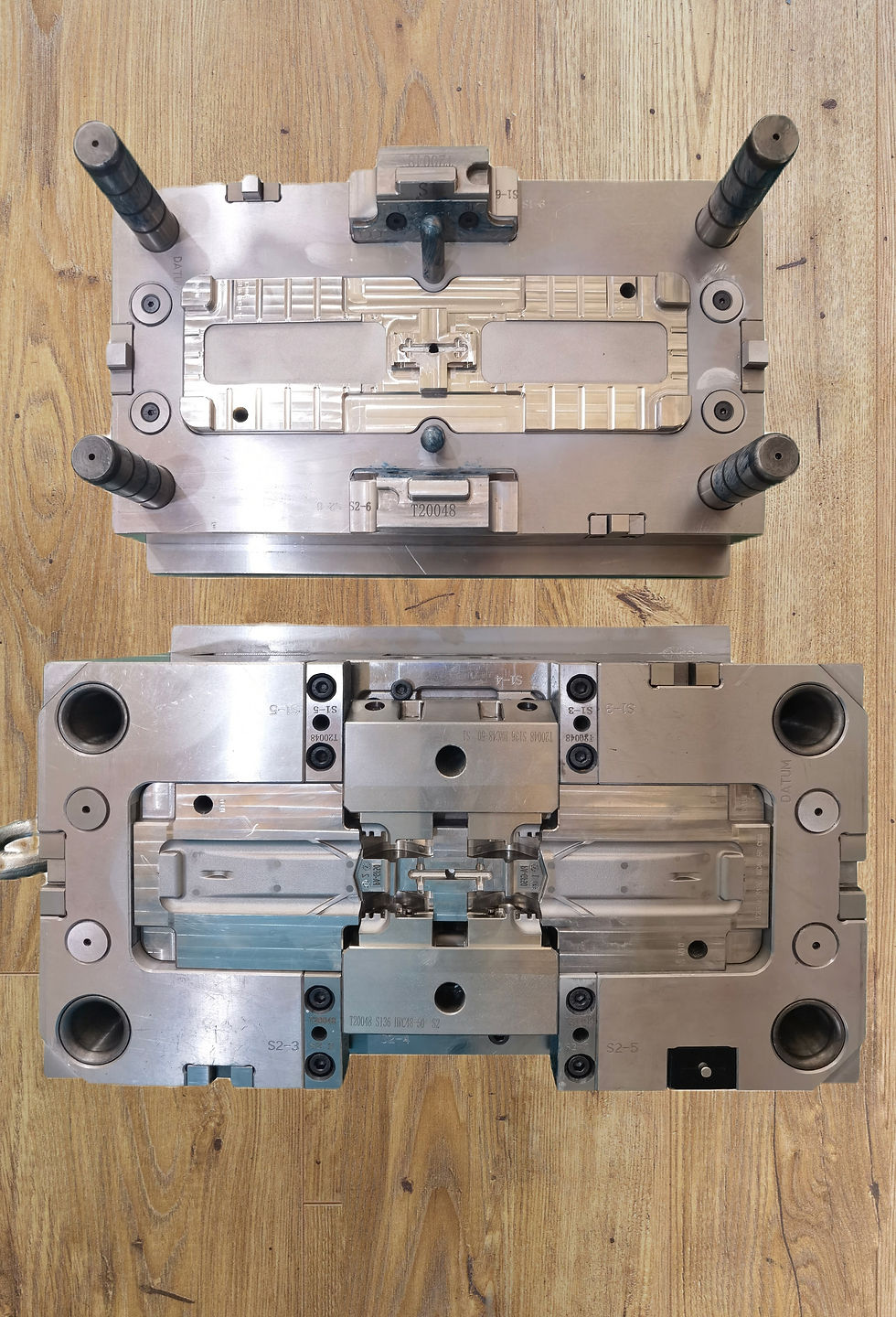

Automotive

Switching between high-performance plastics like glass-filled nylon and ABS is common in automotive. Purging compound prevents material crossover that could lead to part failure or OEM rejections.

_edited.jpg)

Automotive

Consumer Goods

Frequent color and material changes for seasonal or trend-driven products make purging essential to reduce scrap and keep up with tight retail launch windows.

.jpeg)

Consumer Goods

Medical Products

Medical molding demands strict material purity. Purging helps avoid contamination that could compromise compliance or cause entire batches to be scrapped.

.jpeg)

Medical Products

Packaging

Purging helps maintain strength and durability in mailers, wraps, and shipping materials by ensuring clean transitions between recycled and high-performance resins.

.jpeg)

Packaging

Electrical Products

Processing flame-retardant or conductive resins requires clean transitions. Purging ensures these sensitive materials don’t degrade or cause defects in critical components.

.jpg)

Electrical Products

Custom Molders

Custom molders rely on purging to handle rapid changeovers between specialized jobs. It ensures clean runs across varied specs, reducing costly rework or quality issues.

_edited.jpg)

Custom Molders

bottom of page